Test sieves for cereal and other agricultural are part of the greater category of laboratory instruments and are therefore governed by numerous international and national quality standards that specify strict tolerances for sieve apertures, manufacturer certification and regular re-inspection of used sieves. To satisfy the high-quality demands that exist for test sieves in laboratory & industrial use, Blau-Metall utilizes precision manufacturing methods for the production of our sieves and modern Image Dimension Measurement Systems for certification of compliance with the required standards.

Test sieves for cereal and other agricultural are part of the greater category of laboratory instruments and are therefore governed by numerous international and national quality standards that specify strict tolerances for sieve apertures, manufacturer certification and regular re-inspection of used sieves. To satisfy the high-quality demands that exist for test sieves in laboratory & industrial use, Blau-Metall utilizes precision manufacturing methods for the production of our sieves and modern Image Dimension Measurement Systems for certification of compliance with the required standards.

Additionally, quality control standards such as ISO 9000 demand fully traceability of laboratory instruments. Each Blau-Metall sieve has a tamper-proof, 3D laser engraving showing its unique identification number which enabled full traceability of the sieve from its first optical inspection prior to shipment to the customer and all subsequent inspections.

In addition to pre-shipment certification of all test sieves, Blau-Metall offers re-certification services for test sieves – including those from other manufacturers. For re-certification, inspection is carried out according to the methods specified within the respective standard and inspection results are fully documented and delivered to the customer – creating a complete quality assurance solution for your screening equipment.

In addition to pre-shipment certification of all test sieves, Blau-Metall offers re-certification services for test sieves – including those from other manufacturers. For re-certification, inspection is carried out according to the methods specified within the respective standard and inspection results are fully documented and delivered to the customer – creating a complete quality assurance solution for your screening equipment.

Blau-Metall grain test sieves are manufactured in accordance to the following standards:

- EN ISO 5223 (European standard for test sieves for cereals, Oblong & round perforation)

- Tolerances derived from EN ISO 5223 (Non-standard oblong sieves, e.g. 3.00 x 20.0 mm)

- ISO 3310-2 (Test sieves with round apertures)

- ASTM E323 (American standard for test sieves with perforated plates, available upon customer request)

- Tolerances derived from ISO 3310-2 (Non-standard sieves with round apertures, e.g. 3.00 mm)

- DIN 24041 (Standard perforated plate sieves according to industrial tolerances, e.g. 0.5 mm round)

As added value, every ISO 3310 and 5223 test sieve sold via iso5223.com is shipped with a Calibration Certificate conforming to EN 10 204 and showing all relevant sieve parameters obtained via detailed optical inspection of the test sieve.

Inspection Documents

Prior to shipment, each and every Blau-Metall sieve undergoes an optical inspection in accordance with the respective standard using state of the art Image Dimension Measurement Systems with full documentation of inspection results. An individual laser engraving on each sieve, including a unique serial number, allows for clear traceability of each sieve and its inspections.

Certificate of Compliance 2.1

Unless otherwise noted, we issue a free Certificate of Compliance 2.1 according to EN 10204 that attests that the sieve was manufactured according to the standard specified on the sieve label and that the sieve passed the optical inspection requirements of the respective norm. For sieves manufactured in accordance with tolerances, these will be shown on the certificate.

Test Sieve Record Card

For Blau-Metall test sieves according to ISO 3310, EN ISO 5223 and ASTM standards, we issue Test Sieve Record Cards as suggested in DIN ISO 3310 as a measure to keep track of a sieve’s inspection history. The card validates that the sieve underwent optical inspection by the manufacturer and complies with the standard. Additional lines on the card can be used by the operator or other parties conducting re-certification services to log the results of periodic inspections of the sieve to provide an easy means for full documentation that the operator complied with the quality assurance requirements placed upon them by applicable laws, standards or industry guidelines.

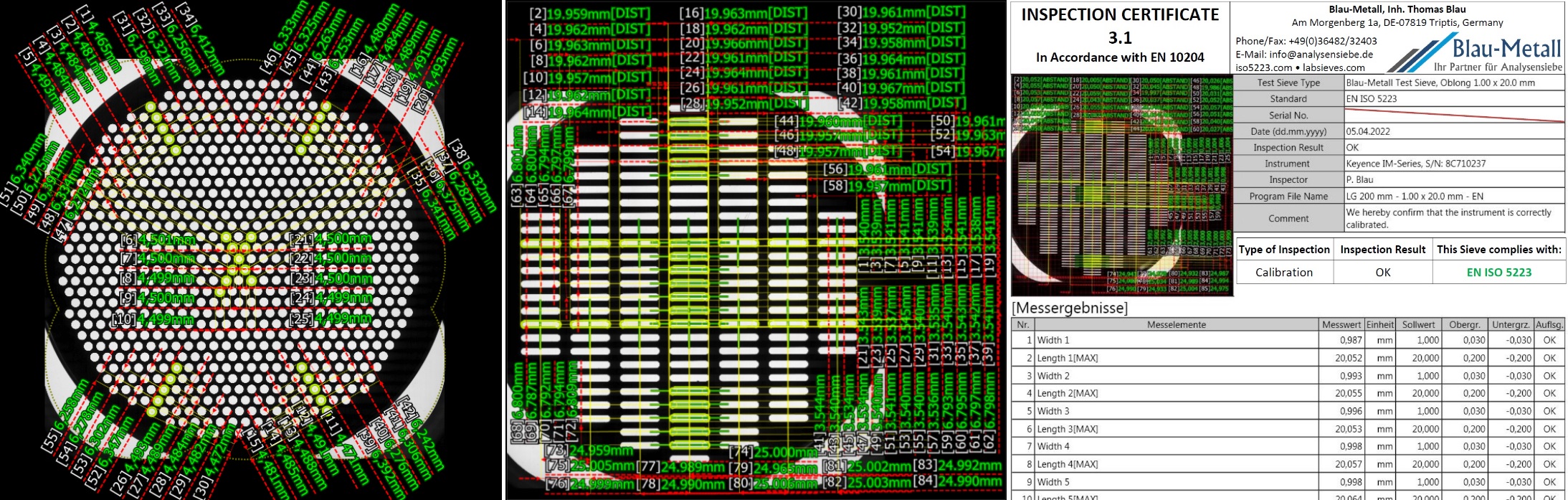

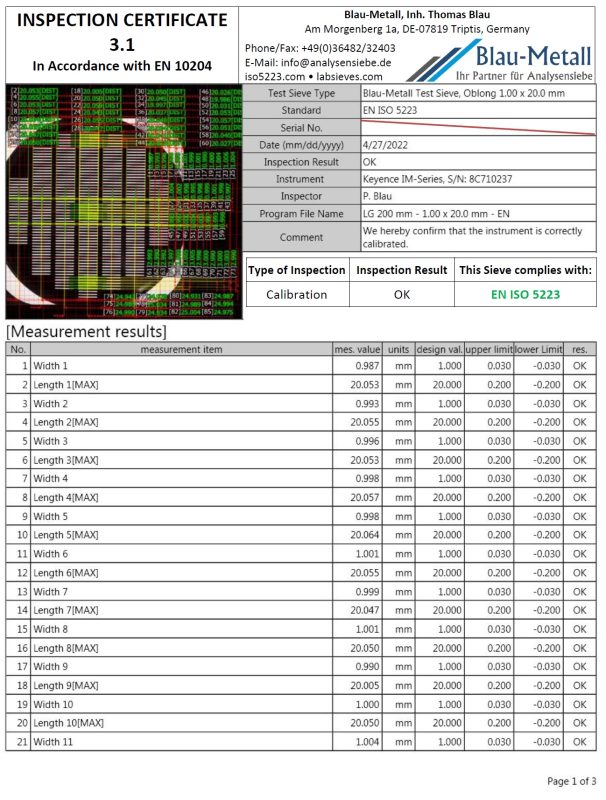

Inspection Certificate 3.1

All sieves sold via iso5223.com comes with an Inspection Certificate 3.1 (EN 10 204), free of any additional charge. These certificates include the detailed inspection report that shows all properties measured as part of the optical inspection process to verify the norm-compliance of the sieve. The inspection can be carried out as Certification according to the measurement requirements outlined in the respective standard or as Calibration in which the number of measured apertures is tripled (with respect to the certification requirement) to add statistical certainty in the results obtained.

Re-Certification

Various national and international standards – such as requirements issued by European agricultural ministries – dictate that test sieves for cereals are to be re-inspected on an annual basis or replaced with newly manufactured equipment.

In times of economic challenges, supply chain issues and limited availability of raw materials, Blau-Metall offers cost-effective re-certification services for all types of ISO 3310 / 5223 grain sieves. Re-certifying test sieves comes at a fraction of the cost of procuring new sieves, reduces environmental strain and eliminates potentially long delivery times for new sieves due to uncertainties in the raw material marketplace.

Our re-certification service starts from € 22.50 per sieve – a 85% saving compared to procuring a new sieve every single year.

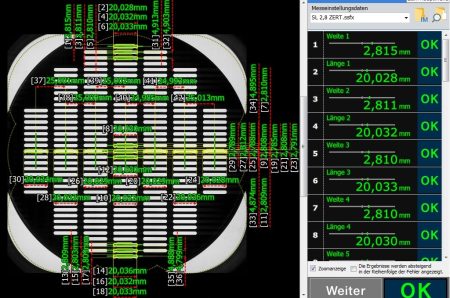

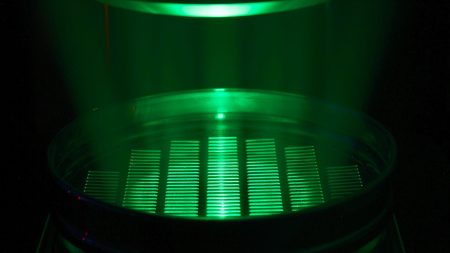

Image Dimension Measurement

Our inspections for certification & re-certification of test sieves are carried out using modern digital image dimension measurement technology. Called for in internationally binding standards is an optical measurement using a “cross section projector with a minimum magnification of 50 x” (EN ISO 5223), “an appropriate measuring device with a reading accuracy of 1 µm or ¼ of the tolerance for the maximum permissible error of ±Y” (ISO 3310-1), “a precision of at least 2.5 μm or 10 % of the (Permissible Variation of Average Opening)” (ASTM E 11).

Our inspections for certification & re-certification of test sieves are carried out using modern digital image dimension measurement technology. Called for in internationally binding standards is an optical measurement using a “cross section projector with a minimum magnification of 50 x” (EN ISO 5223), “an appropriate measuring device with a reading accuracy of 1 µm or ¼ of the tolerance for the maximum permissible error of ±Y” (ISO 3310-1), “a precision of at least 2.5 μm or 10 % of the (Permissible Variation of Average Opening)” (ASTM E 11).

The Digital Image Dimension Measurement System employed by us (IM-7000 by Keyence) satisfies the above criteria fully as well as those of other national & international standards. Employing digital imaging processing technology, Keyence’s IM Series allows for processing of a large number of sieve apertures – exceeding certification & calibration requirements – and delivers an absolute measurement accuracy of ±5 µm in standard operating mode and 0.5 µm in its precision operating mode. Another advantage found in digital image processing systems is the repeatability of results given the user-independent nature of data acquisition.