Blau-Metall Test Sieves

Blau-Metall manufactures test sieves for conventional particle analysis, cereal classification and custom sieving solutions. Our all-stainless-steel test sieves according to ISO 5223 have been in use across Europe for thirty years. Constant improvements in sieve design, aperture precision and quality control ensure our sieves meet the highest standards and stand out for their exceptional quality. We support sustainability by offering economical re-certification options for our sieves.

Upper Safety Edge

No sharp edges for easy handling and sieving by hand as part of on-site sampling. The rounded edge also helps seal the gap between multiple sieves in a stack and prevents any unwanted material from accumulating. The use of NBR gaskets on the outside of the sieves allows cleaning & drying at +80 °C without the need of removing the O-Ring.

Stackable with Ease

Lower edge designed for effortless stacking: Our test sieves are easily compatible with 200 mm sieves of all major test sieve brands and can be easily used in a stack of sieves. Blau-Metall sieves and sieve accessories are also compatible with sieve shakers of all the major manufacturers.

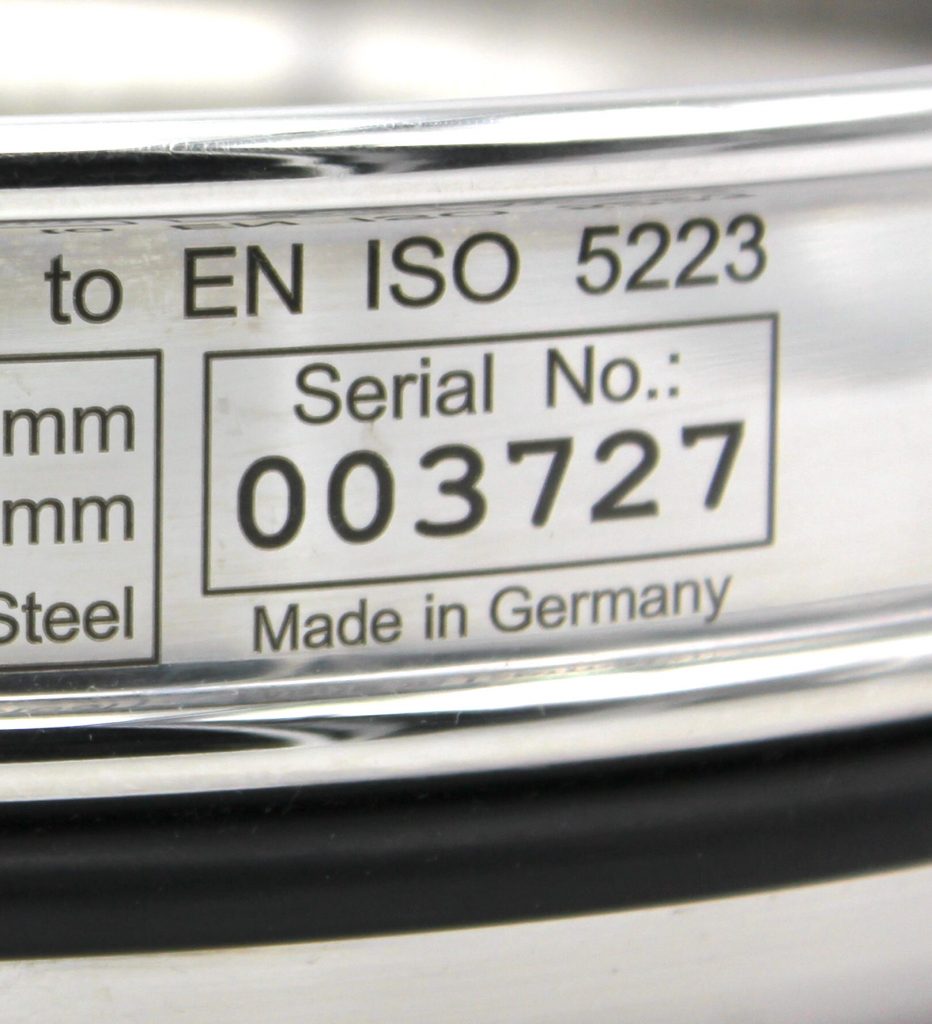

3D Laser Label

- 3D Laser Engraving

- Long-lasting identification

- Tamper-proof through 3D structure

- Font sized for easy reading of sieve size and serial number

- Easily readable in various lighting conditions

- No rivets or gaps for easy handling & cleaning

Full Traceability

Unique, tamper-proof serial number for every sieve allows for full traceability from the initial production through regular inspections as required by numerous national grain intervention boards.

Precision Apertures

- Stainless Steel (AISI 304) perforated plate

- High-precision apertures according to ISO 5223 / ISO 3310-2

- Long lifetime with high reliability for all sieving tasks

- Rigorous optical inspection insures compliance of every single sieve

- Custom perforations available on request

Fully Sealed Design

Each sieve has a dual solder joint to form a highly durable and complete seal between the internal surfaces of the sieve and provide additional reinforcement.

- Fully sealed to avoid cross contamination

- Smooth surface for easy cleaning & quick drying

- Temperature-resistant up to 160 °C

- Corrosion-resistant - no degradation with acidic or caustic cleaners

All Stainless Steel

All sieve components are made from AISI 304 stainless steel to create a highly durable, long-lasting sieve that will maintain its dimensional stability over an extended lifetime of many years.

Sustainability through re-certification instead of re-purchase on an annual basis is a cornerstone of our philosophy.